Diversified Electronics Special Controls

SPM-120-AAA

|

The seal failure module is a specialized

control for monitoring the shaft seal of a submersible pump motor. A

leak is detected by sensing the position of a resistive float switch

installed in the seal cavity. When the resistance drops below the

sensitivity rating, the output relay energizes and the LED illuminates.

When the fault condition clears, the output relay resets automatically.

Back to top |

SPM-120-ABA

|

The dual seal failure module is a specialized

control for monitoring the shaft seals of two submersible pump motors.

Leaks are detected by sensing the conductivity of the contaminating

fluid through probes installed in the seal cavity. When a seal begins to

leak, the seal failure module energizes one of its SPST output relays

indicating that the seal needs to be replaced before the motor is

damaged. The sensitivity of the probe inputs is field adjustable. When

the resistance between one of the probe inputs and the common connection

drops below the sensitivity setting, the corresponding output relay and

LED are activated.

Back to top |

SPM-120-ACA/-ADA

|

The nonvolatile latching temperature switch

relay monitors a normally-closed-low temperature switch. It incorporates

a bistable relay that retains its state during power failures. LEDs

indicate the status of the relay, and connections for an external reset

button are provided for manual control. The reset inputs of multiple

units may be connected to a single push button as long as proper

polarity is observed when making the connections. Under normal

conditions the temperature switch is closed and the relay is

de-energized. When the temperature switch opens, the relay energizes and

latches on until the temperature switch recloses and the reset button is

pressed. The unit will function properly with zero to 2 k ohm of

resistance in series with the temperature switch.

Back to top |

SPM-120-AEE

|

The dual function simplex alarm/relay is a

specialized control for monitoring the shaft seal and stator temperature

of a submersible pump motor. Seal leakage is detected by either a

resistive float switch or a pair of conductive probes installed in the

seal cavity. Over-temperature is detected by a normally-closed-low

temperature switch mounted on the stator. The over-temperature function

incorporates a bistable relay that retains its position during power

failures.

Back to top |

PRT-100

|

The PRT-100 is a handheld tester that takes

the guesswork out of connecting a three-phrase motor. The direction of

rotation of a motor depends on phase sequence of the power line

connections. If the sequence is reversed, the motor will run in the

wrong direction, possibly damaging the equipment connected to the motor.

The PRT-100 identifies the leads of a three-phase motor and detects the

sequence of a three-phase power line. Once the motor and line leads are

properly identified, the motor can be wired so that it turns in the

desired direction on the first try. The unit also detects phase loss and

no voltage conditions.

Back to top |

GFD Series

|

The GFD-XXX is intended for the use on

ungrounded systems to detect and indicate the phase of the first ground

fault condition. This enables corrective action to avoid the potential

hazards resulting from a second ground fault. With nominal 3 phase line

voltage applied, a flashing NORMAL green LED gives indication of a

non-fault condition and integrity of the wire connection to the

corresponding phase.

A Flashing red LED gives positive FAULT indication of either a

phase-to-ground fault, or a lost connection to the corresponding phase.

Back to top |

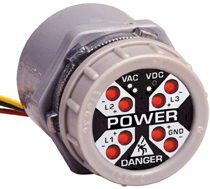

UPA-100 Series

UL Approved

CSA Approved

|

With the green (GND) wire connected to earth

ground, the eight detector UPA-100 visually alerts to the presence of

dangerous AC or DC (Stored Energy) potentials occurring between any

combination of the four monitored input lines (L1, L2, L3, GND). Two LED

indicators are assigned to each input line and are designated "+" and

"-". For each input line carrying an AC potential (bipolar), both the

"+" and "-" LEDs will be active. A DC or Stored Energy potential will

illuminate the "+" LED for the positive line and the "-" LED for the

negative line.

OSHA 1910.147 THE CONTROL OF HAZARDOUS ENERGY

(Lockout/Tagout).

Following the application of lockout or tagout devices to energy

isolating devices, all potentially hazardous stored or residual energy

shall be relieved, disconnected, restrained, and otherwise rendered

safe.

(d)(5)(ii)

If there is a possibility of reaccumulation of stored energy to a

hazardous level, verification of isolation shall be continued until the

servicing or maintenance is completed, or until the possibility of such

accumulation no longer exists.

(d)(6)

"Verification of Isolation." Prior to starting work on machines or

equipment that have been locked out or tagged out, the authorized

employee shall verify that isolation and de-enegerization of the machine

or equipment have been accomplished.

Back to top |

SP-0313

MotoReset

|

When the voltage to your equipment is lost

due to tripped breakers, blown fuses, or loss of utility power. Simply

remove the existing cord set plug from the outlet, plug into the

properly sized MotoReset device, and plug the assembly back into the

outlet. The unsupervised unintentional automatic restart of equipment

when breakers are reset or when utility power is restored after an

outage. Restoration of utilities with equipment control switches left in

the “ON” position will not restart with the MotoReset in place. The need

for additional, potentially hazardous, manual reset pushbuttons. The

MotoReset turns the equipment existing ON/OFF switch into a manual reset

switch. The operator does not have to leave the immediate vicinity, nor

the normal operating position of protected equipment, to safely reset

after an outage. Simply switch the equipment “OFF” to reset to normal

operation.

Back to top |

CCT Series

|

The CCT Series, Crank Cycle Timer, provides a

sequential Crank/Reset signal for starting commercial and industrial

portable, standby, and emergency power generators. When the supply

voltage is applied to the input terminals, Load #1 energizes and the

Crank Time (t1) begins. Upon completion, Load #1 de-energizes and the

rest time (t2) begins. Upon completion, Load #1 energizes. This

Crank/Rest action continues for a preselected number of cycles, where

upon completion, Load #1 locks in a de-energized state and Load #2

energizes. Reset is accomplished by interrupting the supply voltage.

PLEASE NOTE: This timer has been

obsoleted by ATC/Diversified. Please contact us at 800-479-4783

regarding a low-cost PLC replacement offering.

|

Low Cost |

|

Adjustable Crank/Reset Delay |

|

CMOS Technology |

|

Totally Solid State Circuitry |

|

Selective Number Of Cycles |

Back to top

|

|

|